Custom Racks

Built for Your Needs

Need Help?

Rack

Solutions

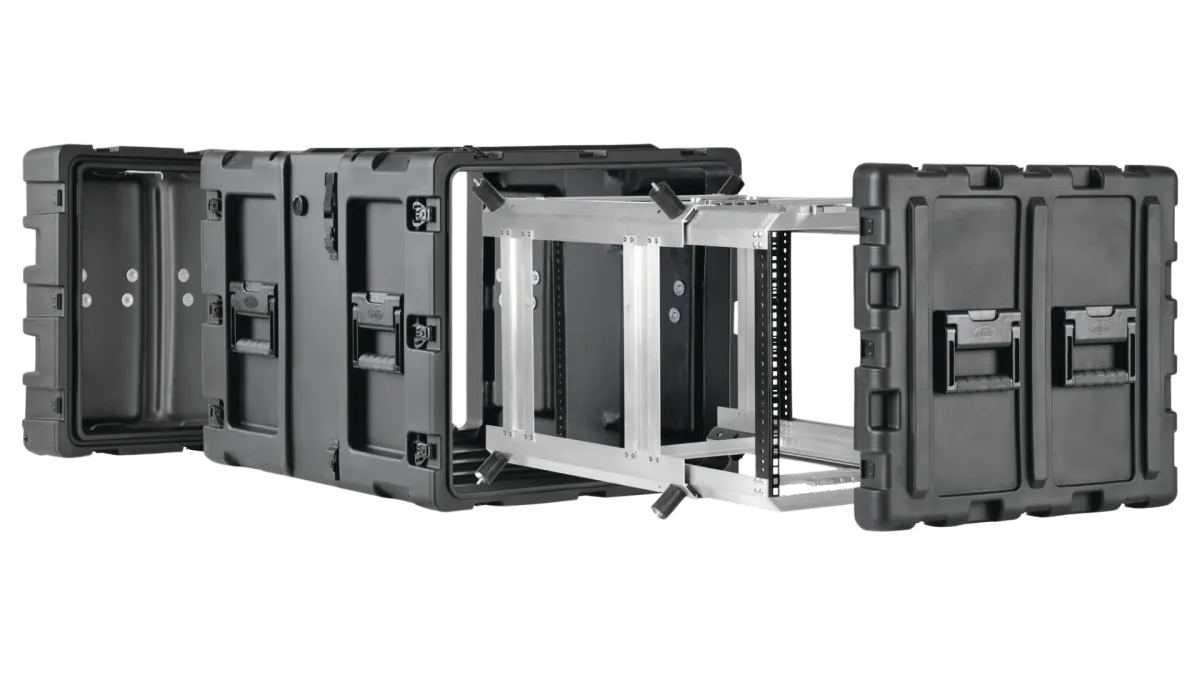

MIL-STD-810H Shock Racks 20”, 24”, and 30” Depths

A rugged MIL-STD-810H roto-molded shell ensures industry-leading strength and impact resistance, with molded-in stacking ribs and lugs designed to stack with competitive manufacturer’s cases.

24”, 28”, and 30” Shock Racks

Features affordable shock isolation with an ultra-strong aluminum interior H-shaped frame, removable casters, and a compound hinge system for fast deployment

20” Shock Absorbing Rolling Racks

Roto-molded 20” deep rack frame with pull handle and wheels, a molded valance and rubber gasket on both front and rear doors for water resistance, and elastomeric shocks

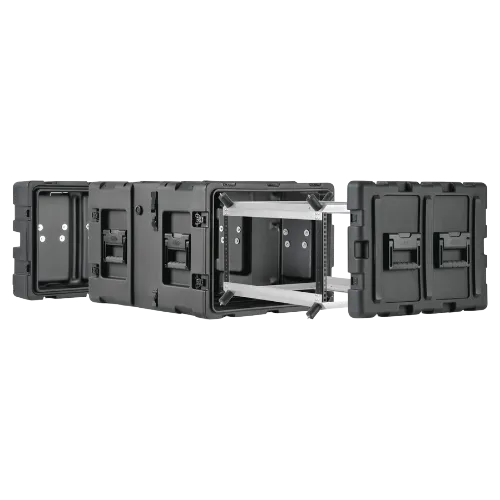

20” Roto Shock Racks

Features threaded steel rails, an ultra-strong H-shaped interior frame, adjustable elastomeric shocks, and secure molded-in handles

3RR Removable Shock Racks

3RS Static Shock Racks

Injection Molded Racks

Lighter than conventional molded racks for fast deployment of communications gear

Fly Racks

Featuring both injection molded cases and racks, Fly Racks are lighter than standard shocks racks and under 62 linear inches for shipping or flying

MOBCOM Flyers

Compact and perfect for mobile deployment of communications gear in the field

Non-shock Roto Racks

Rugged, roto-molded non-shock racks available in many sizes, depths, and wheel options

Rack

Accessories

MIL-STD-810H Shock Racks 20”, 24”, and 30” Depths

A rugged MIL-STD-810H roto-molded shell ensures industry-leading strength and impact resistance, with molded-in stacking ribs and lugs designed to stack with competitive manufacturer’s cases.

Shockmount Roto Caster Kit

Roto-molded caster board with 3” locking wheels for transport of stacked 20” shock racks

Support Rails

Zinc plated steel rails to support additional weight

• 20” shock racks

• 24” shock racks

•28” shock racks

• 30” shock racks

Injection Molded Racks

Lighter than conventional molded racks for fast deployment of communications gear

Accessory Pocket Kits

Zippered pocket with hardware that attaches to case lids

• 20” x 10” x 3”

• 20” x 15.5” x 3”

Caster Accessory Bag Kit

Lid-mounted accessory bag measuring 12” x 9.5” x 3.5” with compartments for storing shock rack casters

MIL-STD-810H Shock Racks 20”, 24”, and 30” Depths

A rugged MIL-STD-810H roto-molded shell ensures industry-leading strength and impact resistance, with molded-in stacking ribs and lugs designed to stack with competitive manufacturer’s cases.

Shipping Label Plate Kit

12” x 7” aluminum label plate

with installation hardware

Rack Mount Hardware

Pack of 12 clips and screws for mounting electronics

Frequently Asked Questions

What types of products can benefit from custom foam packaging?

Custom foam packaging is ideal for a wide range of products, including electronics, fragile glassware, medical equipment, automotive parts, and more. Our foam inserts are designed to fit the specific shape and size of your products, ensuring optimal protection during shipping and storage.

How do I know which foam packaging solution is right for my products?

Our team works closely with you to understand your product's size, shape, and fragility. We offer personalized consultations to help you select the right foam material, whether it’s polyurethane, polyethylene, or eco-friendly options, to ensure your products are properly protected.

Are your foam packaging solutions eco-friendly?

Yes, we offer sustainable packaging options, including biodegradable and recyclable foam materials. We are committed to reducing environmental impact while providing the same level of protection and durability your products need.

How quickly can I expect my custom foam packaging to be delivered?

We strive for fast and efficient turnaround times. Depending on the complexity of your custom design and order size, we typically deliver within [insert timeframe], ensuring your packaging arrives when you need it.